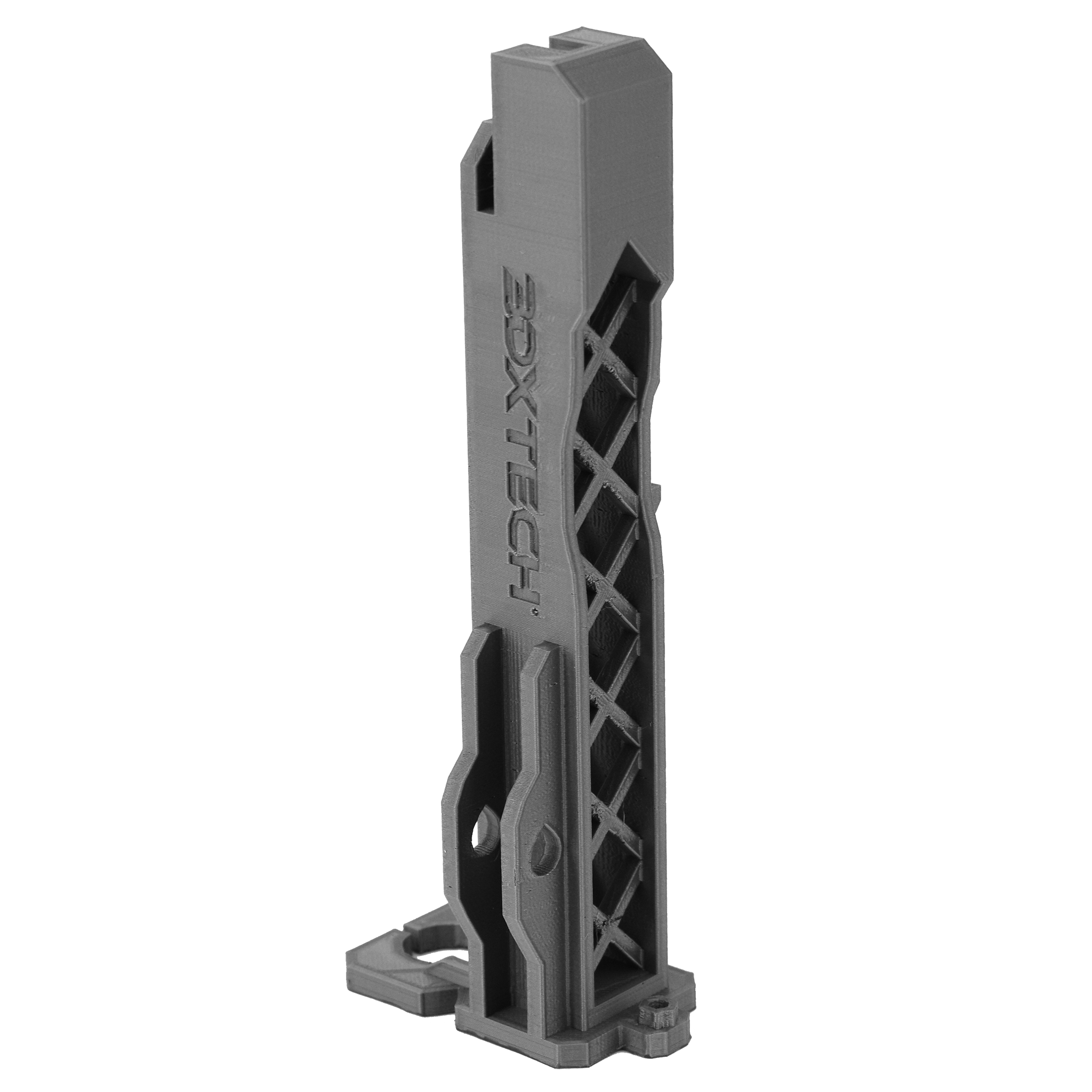

Made in the USA using premium PETG and High-Modulus Carbon Fiber (not carbon powder or milled carbon fibre).

CarbonX™ CF-PETG is an improved CF reinforced 3D printing filament vs. the competition.

This filament is ideal for anyone that desires a structural component with high modulus, excellent surface quality, dimensional stability, light weight, and ease of printing.

Carbon fibre reinforced filaments are abrasive and can wear out a brass or aluminum nozzle. We recommend our Hardened Steel Nozzles

Benefits of CarbonX™ CF-PETG include:

- Superior Chemical Resistance vs. ABS

- Amorphous: Low and near isotropic shrinkage

- Low moisture absorption: 3X lower vs. ABS

- Very low Odor emitted during printing

- Wide processing range: 230 - 270°C

Chemical Resistance: Unstressed tensile bars moulded of PETG exhibit good resistance to dilute aqueous solutions of mineral acids, bases, salts, and soaps, and to aliphatic hydrocarbons, alcohols, and a variety of oils. Halogenated hydrocarbons, short chain length ketones, and aromatic hydrocarbons dissolve or swell the plastic.

New Data: We updated the mechanical and thermal data on our carbon fiber grades.

*Please note: 2kg and 4kg reels are special order and generally take 6 days to ship.

Email us for more info on this jason@formtech.co.nz

Recommended Print Conditions:

- Extruder: Ideally 230 to 260°C

- Platform Temp: 70 to 90°C

- Platform Prep: Clean glass w/ Kapton Tape, PVA-based glue, Hairspray

- Nozzle: We currently recommend minimum 0.40mm orifice.

- Layer Height: Ideal layer height is 60% of nozzle diameter. We do not recommend printing layers below 0.2mm with CF Grades.

- Carbon fiber filament is more abrasive than unfilled materials, so extended use will result in more wear on your nozzle.

- Support: Our Aquatek water soluble support works great to create complex parts.

- Drying Instructions: Please see the following instructions for when you want to dry out this filament.

![iSANMATE High-Speed PLA 3D Printer Filament Rainbow 03 [Fairy Floss] 1kg roll](http://www.formtech.co.nz/cdn/shop/files/High-speed-PLA-Rainbow-1-600x600_70x.jpg?v=1713148368)

![iSANMATE High-Speed PLA 3D Printer Filament Rainbow 02 [Cotton Candy] 1kg roll](http://www.formtech.co.nz/cdn/shop/files/High-speed-PLA-Rainbow-02-2-600x600_70x.jpg?v=1713147902)

![iSANMATE High-Speed PLA 3D Printer Filament Rainbow 01 [Lollipop] 1kg roll](http://www.formtech.co.nz/cdn/shop/files/High-speed-PLA-Rainbow-01-1-600x600_70x.jpg?v=1713147615)

![iSANMATE PLA+ MATTE RAINBOW 01 [Harvest Glow] 1.75mm Filament 1kg roll](http://www.formtech.co.nz/cdn/shop/files/PLA-rainbow-filament-1-600x600_70x.jpg?v=1713145773)